Continuing from Part 1, Part 2 introduces the remaining 10 companies (companies 11-20) that AM Insight Asia (AMIA) found noteworthy at TCT Japan 2026. From materials and filaments to hybrid manufacturing systems and distribution networks, this coverage highlights the diverse range of solutions and approaches shaping Japan’s additive manufacturing landscape. The order of coverage remains random and carries no special significance. This selection reflects AMIA’s subjective editorial judgment and does not imply that unlisted exhibitors are not noteworthy.

11. Aichi Sangyo

Company Overview:

Aichi Sangyo Co., Ltd. is an engineering trading company with over 80 years of history that has introduced cutting-edge welding, melting, and fusion technologies to the Japanese market. In 2014, the company signed a distributor agreement with SLM Solutions (now Nikon SLM Solutions) and has built a track record in the metal 3D printing field. At TCT Japan 2026, they exhibited additive CAM software from Dyndrite Corporation (USA), among other technologies. This followed the Dyndrite Roadshow 2026 held the day before, organized by Aichi Sangyo.

Why AMIA Noticed:

Asia’s metal AM market stands at a critical juncture. As hardware becomes more sophisticated and affordable, many buyers in Japan and elsewhere focus solely on machine specifications—laser count, build volume, layer thickness. However, 3D printers are just one element within the entire manufacturing process, and whether the software required for one’s process is compatible becomes an important decision factor. For users who need Dyndrite, purchasing incompatible equipment is meaningless. Selection must be made with a holistic view of the entire process, not just the machine alone.

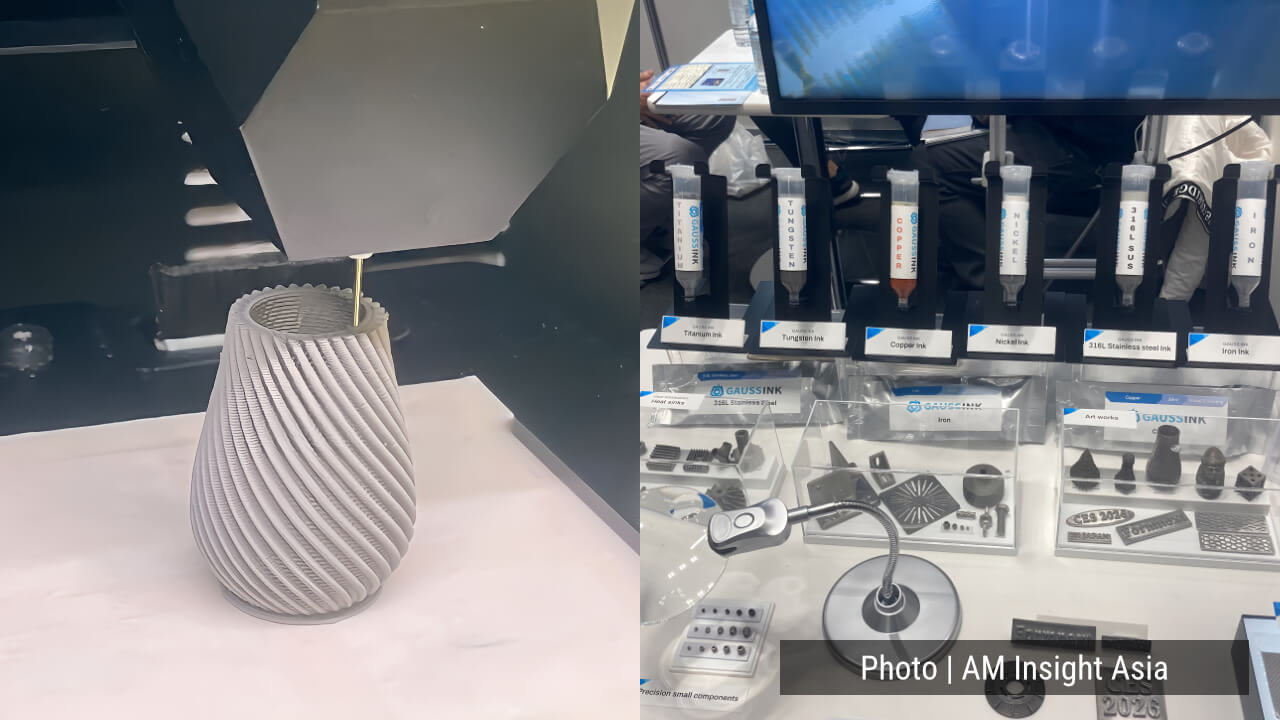

12. Metal Printing

Company Overview:

Metal Printing Inc. is a South Korean company founded in 2018 as a materials development company, led by CEO Daesan Kim. At TCT Japan 2026, they exhibited the Gauss MT90, which won a CES 2026 Innovation Award. The machine employs Paste-based Metal Extrusion (PME) technology, using metal paste (gel-like metal material) for a new type of metal 3D printing. After printing, parts are heat-treated in a sintering furnace. Priced at $35,000, the sintering furnace appears to be of similar size and price range. The company offers proprietary materials under the GAUSS Ink brand and displayed printed samples in stainless steel and copper.

Why AMIA Noticed:

At TCT Japan 2026, having decided to exhibit at the last minute after CES, they had a small booth in a back corner deadspace, which many visitors may have missed. Traditional metal AM used powder or filament materials, but a new material form—gel—has emerged. Priced at $35,000 with a compact, affordably priced sintering furnace, it significantly reduces introduction costs. While the build size is small, it shows sufficient potential for prototyping and production of small parts.

13. Ningbo Homelink Eco-iTech

Company Overview:

Ningbo Homelink Eco-iTech Co., Ltd. is a biodegradable plastic products manufacturer based in Ningbo, China, established in 2009. Known as a global supplier of plastic tableware to major retailers such as IKEA, Walmart, Costco, and Target, the company operates 17 factories and holds various international certifications (HACCP, ISO9001, BRC, etc.). At TCT Japan 2026 booth (3S-G13), they exhibited 3D printing filaments including PLA-HS, PLA-SILK, and PLA-Pro.

Why AMIA Noticed:

It is noteworthy that a large-scale manufacturer supplying products to major global retailers such as IKEA, Walmart, Costco, and Target has also entered the 3D printing filament market. The company provides OEM supply to many filament brands and can also function as a partner for Japanese companies looking to launch their own filament brands. For the Japanese market, this suggests the possibility that global players with such manufacturing infrastructure may enter, rather than individual filament manufacturers.

14. Phaetus

Company Overview:

Phaetus is a Chinese manufacturer of high-end core components for 3D printers, specializing in hotends, nozzles, and extruders. Known for high-performance parts such as the Dragon, Dragonfly, and Rapido hotends, as well as tungsten carbide and silicon carbide nozzles. The company also offers compatible parts for major printer manufacturers including Bambu Lab, Prusa, and Creality. At TCT Japan 2026, they exhibited hotends, nozzles, filaments, and printed samples. They are well recognized among core consumer users.

Why AMIA Noticed:

Japan’s consumer 3D printing market is quite active, partly due to the influence of companies like Bambu Lab, and the aftermarket is expanding accordingly. Peripheral equipment and parts manufacturers beyond printer makers, such as Phaetus, are likely to gradually increase their brand recognition in Japan. The growth of the aftermarket serves as an indicator of the overall ecosystem’s maturation.

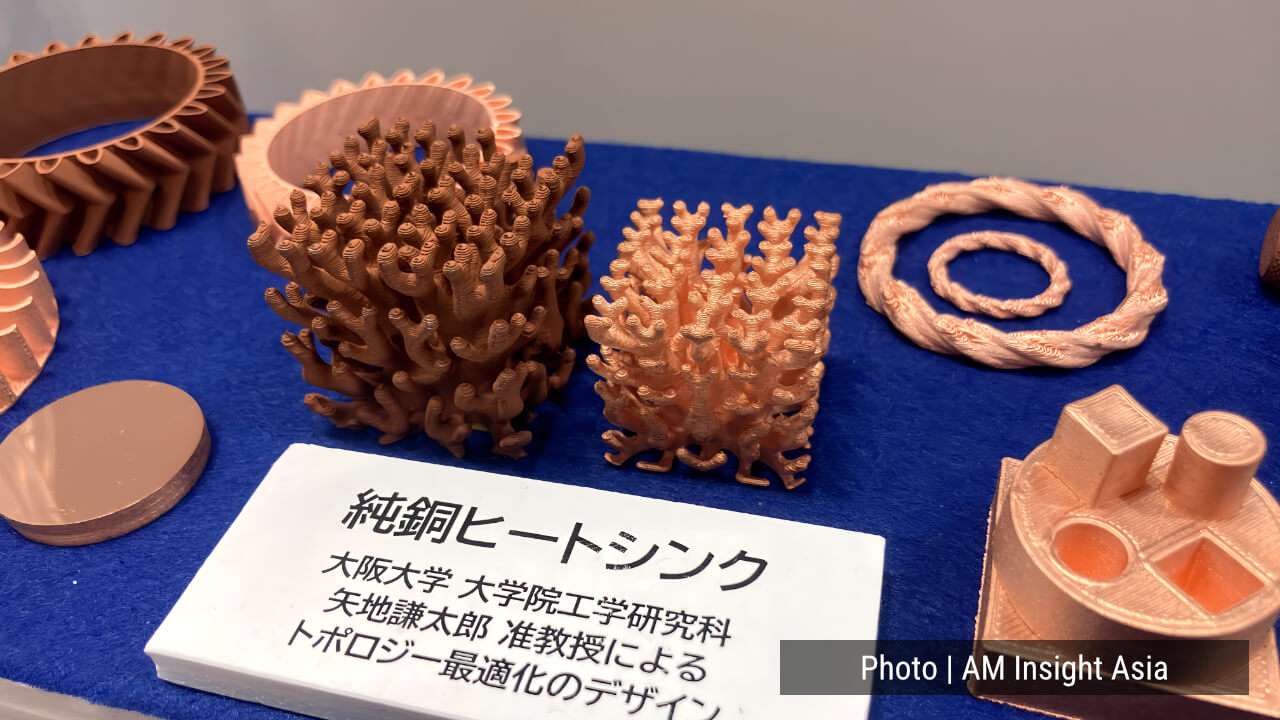

15. Dai-ichi Ceramo

Company Overview:

Dai-ichi Ceramo Co., Ltd. is a group company of Daiichi Kogyo Seiyaku based in Higashiomi, Shiga Prefecture, manufacturing and selling metal and ceramic filament materials for 3D printers. They handle materials such as SUS316L, 17-4PH, pure copper, titanium, and alumina, which can be printed at 240°C, making them compatible with standard FDM printers like the Bambu Lab A1. While conventional technologies require debinding processes using organic solvents, the company’s filaments complete the process through furnace debinding and sintering alone, achieving safety that allows handling printed parts with bare hands. The products are also available through the Ultimaker Marketplace for international purchase. At TCT Japan 2026, they exhibited filaments and metal printed samples, and demonstrated actual printing with a Bambu Lab A1.

Why AMIA Noticed:

Since printing can be done easily even with inexpensive 3D printers, if the sintering hurdle can be overcome, almost no investment in the 3D printer itself is required. While identifying suitable applications remains a future challenge, it demonstrates new possibilities for desktop metal additive manufacturing.

16. Creality

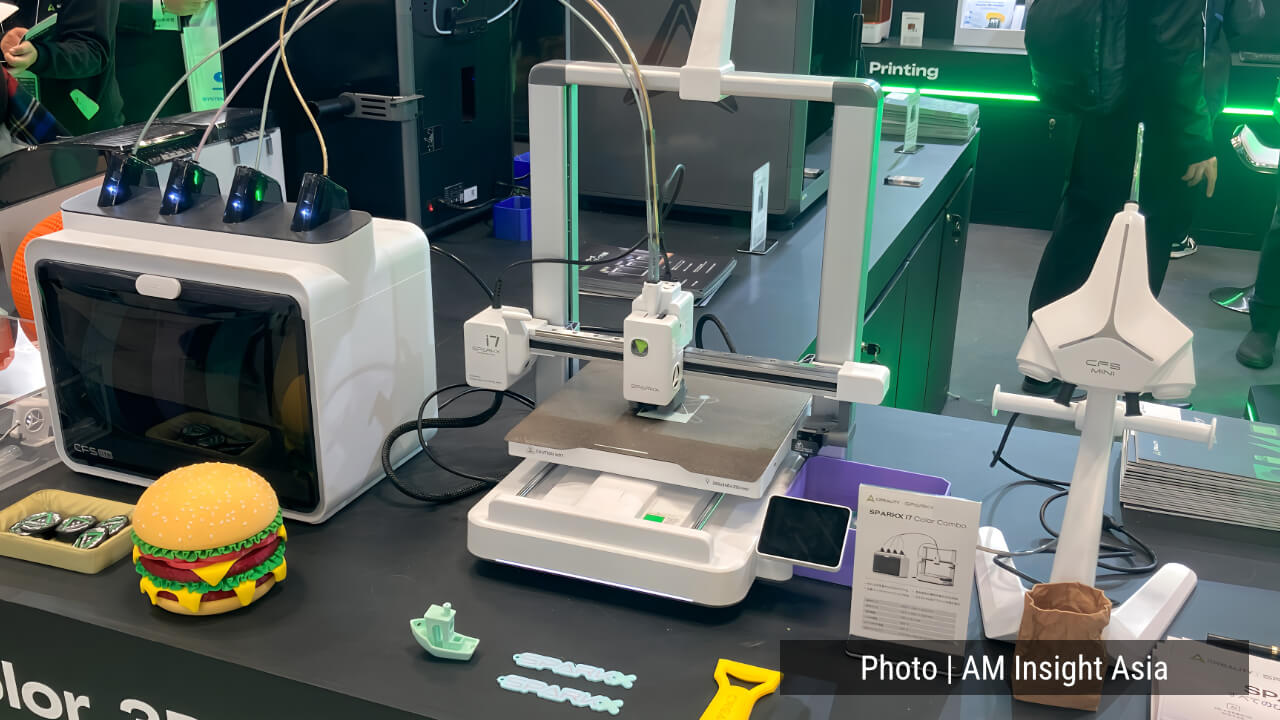

Company Overview:

Creality is a major Chinese 3D printer manufacturer known for its Ender-3 series. At TCT Japan 2026, they exhibited the SPARKX i7, which had just been announced at CES 2026. The SPARKX i7 is an AI-powered four-color multicolor printer that achieves a 50% reduction in material waste compared to conventional systems. It features a quick-swap hotend and AI-powered camera for real-time monitoring, and won Tom’s Hardware’s CES 2026 Best 3D Printer award. Other products on display included the Ender-3 V4, Falcon T1 laser engraver, and Sermoon P1 3D scanner.

Why AMIA Noticed:

Exhibiting the latest model just announced at CES 2026, it is noteworthy for incorporating advanced features such as AI capabilities and four-color multicolor support at a low price point. Additionally, by offering their own 3D scanner, the Sermoon P1, the workflow of scanning and then printing becomes smoother, which is also notable. This demonstrates both the speed of technological innovation in the consumer 3D printer market and the movement toward building an ecosystem.

17. Tangshan Weihao Magnesium Powder

Company Overview:

Tangshan Weihao Magnesium Powder Co., Ltd., founded in 2000 and based in Qian’an City, Hebei Province, is a specialist manufacturer of high-purity atomized spherical magnesium powder and alloy powders. As a core drafting unit for the national standard “Magnesium and Magnesium Alloy Powders for Additive Manufacturing” (GB/T 44151-2024), the company exports products to 37 countries and regions. Their product lineup includes Mg-Zn, Mg-Li, Mg-Al-Zn, Al-Mg, biomedical WE43, ZK61, and others, serving applications in aerospace, welding, hydrogen storage, powder metallurgy, and more. At TCT Japan 2026, they exhibited specialty material powders such as magnesium and tungsten, along with printed samples.

Why AMIA Noticed:

The fact that a manufacturer specializing in specialty materials such as magnesium and tungsten exhibited in the Japanese market is itself noteworthy. Rather than generic stainless steel or titanium, the increase in suppliers handling materials necessary for lightweighting and special applications demonstrates the diversification of Asia’s AM materials ecosystem. The exhibition of both materials and printed samples to demonstrate actual applicability is also significant.

18. Gutenberg

Company Overview:

Founded in 2021 and based in Ota Ward, Tokyo, Gutenberg is an industrial high-speed 3D printer development venture. Committed to domestic design and manufacturing, the company offers the “G-ZERO series,” which supports engineering plastics. Featuring high-speed printing with a maximum speed of 700mm/s and maximum acceleration of 30,000mm/s², the company has over 300 installations across Japan. With high compatibility with POTICON filament (PPS) co-developed with Otsuka Chemical, it achieves high-quality output approaching injection molding. In 2025, they announced the G-ZERO MP1, a model specialized for PEEK printing, which was exhibited at TCT Japan 2026.

Why AMIA Noticed:

Their booth is always popular at exhibitions, demonstrating their presence as a domestic industrial 3D printer manufacturer. While initially focused on high-speed capabilities, the company has evolved to meet the precision and stability requirements of industrial applications, attracting attention from major industries including automotive. Particularly significant is the optimization of material and printer combinations achieved through co-development of POTICON filament with Otsuka Chemical. The exhibition of the G-ZERO MP1, specialized for PEEK printing, also attracted attention. The rapid support system enabled by domestic design and manufacturing, combined with clear market positioning for engineering plastics compatibility, represents a key differentiation factor in Japan’s industrial 3D printer market.

19. Sunstella

Company Overview:

Sunstella is a specialized 3D printer distributor that serves as the official Japanese distributor for Polymaker and handles numerous brands including Bambu Lab, Creality, INTAMSYS, REVOPOINT, SHINING 3D, Tiertime, and Phrozen. The company offers a comprehensive range of products from FDM printers and resin printers to 3D scanners, filaments, resins, and peripheral equipment. With showrooms nationwide, the company provides student discounts, volume purchase discounts, and technical support services. At TCT Japan 2026, they exhibited 3D printers including Bambu Lab and INTAMSYS.

Why AMIA Noticed:

As the official Japanese distributor for Polymaker, the company has a strong reputation in materials and demonstrates highly active business operations. Notably, INTAMSYS is an industrial 3D printer used in skills competitions such as WorldSkills, making their role as a domestic distributor particularly significant. By handling multiple brands, the company accumulates information from many users, likely giving them strength in understanding equipment characteristics and comparisons. With high recognition among domestic 3D printer distributors, Sunstella provides an environment where users can select equipment and materials according to their purposes. Their active exhibition presence plays an important role in promoting 3D printer adoption in the Japanese market.

20. Matsuura Machinery Corporation

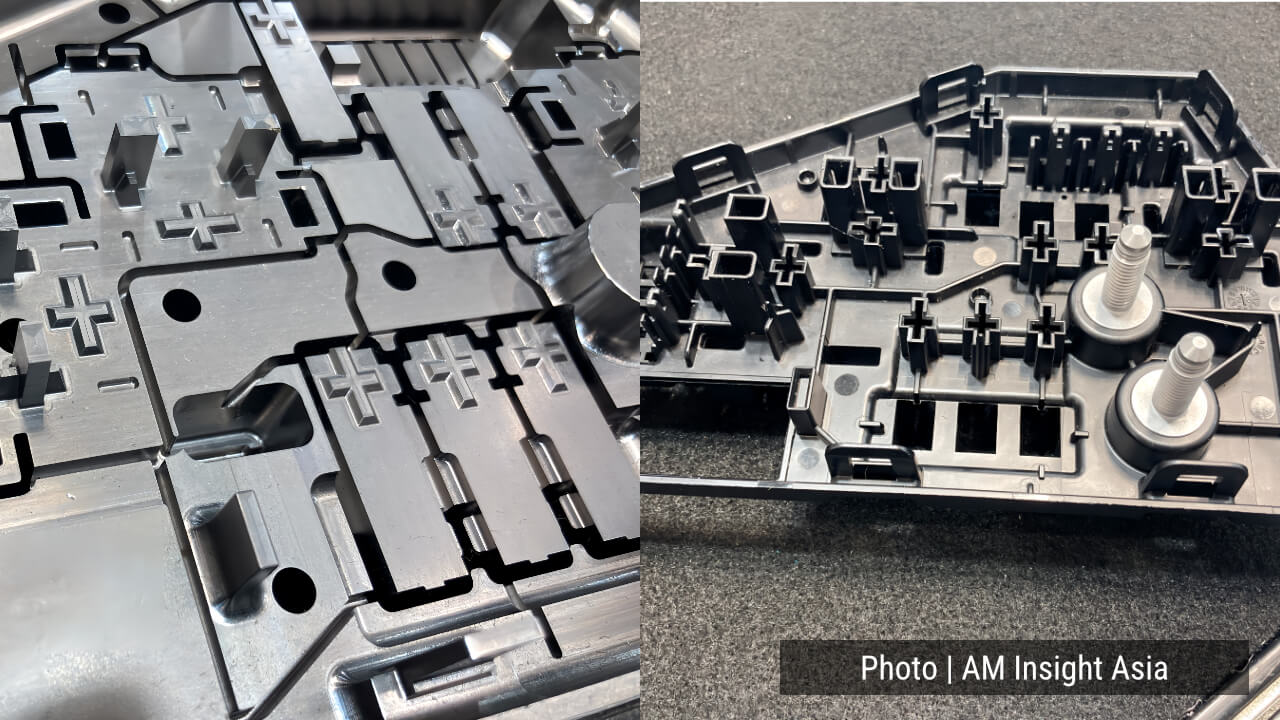

Company Overview:

Matsuura Machinery Corporation, a machine tool manufacturer, offers the LUMEX series, a hybrid metal 3D printer that realizes both laser sintering technology (metal optical shaping) and high-precision cutting in a single machine. Completing shaping in one machine and one process, it achieves high machining accuracy and surface roughness equivalent to machining centers. It is utilized for mold production (such as shortening injection molding cycles through three-dimensional cooling channels) and manufacturing parts with complex internal structures. At TCT Japan 2026, they exhibited numerous mold samples and part samples produced with LUMEX.

Why AMIA Noticed:

The precision of molds created through hybrid technology combining AM and cutting is impressive no matter how many times it is seen. By combining cutting with laser sintering to achieve high precision unattainable by laser sintering alone, the quality of the exhibited mold samples clearly demonstrates practicality in injection molding. They are significant as a Japanese machine tool manufacturer who has elevated AM technology to a practical level.

Part 2 Summary

Part 2 introduced 10 companies including material manufacturers, distributors, and hybrid manufacturing systems. Combined with Part 1, the 20 companies highlighted reveal the diversity of Japan’s AM market at TCT Japan 2026. Following official statistics release from organizers, AMIA plans comprehensive articles analyzing attendee numbers, exhibitor trends, and market developments.