Shenzhen-based AtomForm officially unveiled its 12-nozzle 3D printer, the Palette 300, at CES 2026 in Las Vegas on January 6, 2026. This desktop 12-nozzle 3D printer enables simultaneous use of up to 36 colors and 12 materials in a single print, addressing the long-standing filament waste problem in multi-color printing with up to 90% waste reduction.

AtomForm and MOVA Group Background

AtomForm was founded in October 2023 as an emerging company backed by MOVA Group, a Beijing-based robotic lawn mower manufacturer that has achieved rapid growth in European and North American markets through LiDAR technology. Jagger Shang, AtomForm’s Head of Product, previously served as Director of Smart Hardware Product Projects at MOVA, where he built a robotic lawn mower team that generated over 400 million RMB in revenue during its first year. Prior to MOVA, Shang worked as a project leader at a world-leading professional-grade 3D printing company, successfully launching multiple industrial-grade machines.

OmniElement™ 12-Nozzle System Innovation

The core technology of the Palette 300 is AtomForm’s proprietary “OmniElement™ Automatic Nozzle Swapping System.” This 12-nozzle 3D printer features independent, filament-dedicated nozzles, completely eliminating the filament purging and reloading required in conventional single-nozzle systems during color changes.

Specifically, the 12 nozzles can connect up to 36 filament spools (in a 3-colors-per-nozzle configuration) and combine 12 different material properties (flexibility, rigidity, transparency, etc.) within a single model. For example, users can print figurines with flexible filament at joints, rigid filament for outer shells, and multi-color filament for decorative parts—all in one print without painting.

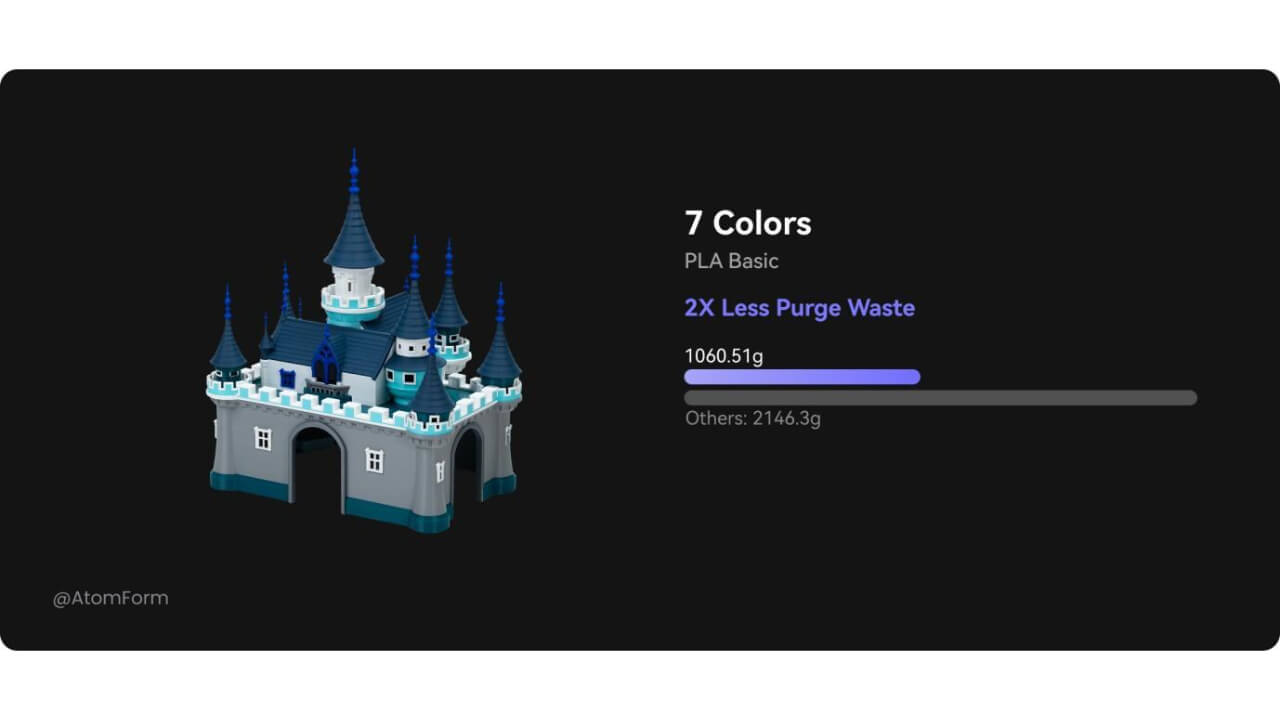

Conventional multi-color 3D printers waste substantial filament by purging existing material and loading new colors with each swap, often consuming more material than the actual model requires. The Palette 300’s 12-nozzle system virtually eliminates this purging process through independent nozzles, reducing waste by up to 90%.

High-Speed, High-Precision Technical Specifications

The Palette 300 delivers industrial-level performance with a maximum print speed of 800 mm/s and acceleration of 25,000 mm/s². The build volume measures 300×300×300 mm, accommodating large models or batch printing of multiple parts.

Precision management utilizes over 50 smart sensors and 4 AI-powered cameras to execute automatic nozzle calibration, pre-detect minute defects, and perform real-time quality monitoring. This significantly improves first-time success rates while reducing time and filament waste from print failures.

Additionally, the printer prioritizes quiet operation with noise levels maintained below 48 dB. A built-in air purification system makes it suitable for shared spaces including homes, classrooms, and offices.

RFD-6 Filament Management System

The Palette 300 connects to up to 6 AtomForm RFD-6 Filament Boxes, managing a total of 36 filament spools. Each box features independent drying functionality that maintains filament quality continuously, even during printing. This enables stable use of moisture-sensitive materials like nylon and PVA.

Competitive Landscape: Snapmaker U1 Comparison

The Palette 300’s announcement symbolizes intensifying competition among Chinese companies entering the high-performance desktop 3D printer market. Shenzhen-based Snapmaker announced the U1 (4-nozzle tool-changer system) on Kickstarter in August 2025, raising $20.6 million from approximately 20,680 backers. The U1 employs a 4-nozzle physical swapping approach with 5-second exchange capability, contrasting with the Palette 300’s fixed 12-nozzle configuration.

The fundamental difference between these approaches lies in nozzle count and swapping methods. Snapmaker’s U1 prioritizes flexibility with 4 physically interchangeable nozzles, while the Palette 300 emphasizes efficiency by eliminating swap time entirely through 12 fixed nozzles.

Release Schedule and Pricing

The Palette 300 is scheduled for commercial release in Q2 2026 (April-June), with a Kickstarter pre-order campaign planned for Q1 2026 (January-March). Early-bird pricing is expected to start at $1,499.

Jagger Shang stated, “The Palette 300 isn’t about incremental improvement—it’s about removing the long-standing barriers of multi-color, multi-material 3D printing. With 12 nozzles, intelligent filament management, and AI precision, creators don’t have to choose between detail, color, material diversity, or speed.”

Rise of Chinese Companies in Low-Cost Desktop Market

The Palette 300’s announcement reflects the growing presence of Chinese companies in the low-cost desktop 3D printer market. Snapmaker (Shenzhen), AtomForm (Shenzhen), Bambu Lab (Shanghai), and Creality (Shenzhen) are consecutively launching high-performance machines in the $500-$2,500 price range.

These companies share a common strategy of market validation and global community building through Kickstarter. Snapmaker U1’s $20.6 million funding success demonstrated strong demand for multi-color and multi-material capabilities. AtomForm similarly plans to launch a Kickstarter campaign in Q1 2026.

AtomForm’s 12-nozzle fixed configuration approach contrasts with Snapmaker’s 4-nozzle swapping method. While theoretically efficient, actual precision, reliability, and maintainability await market evaluation. Notably, since no live demonstration was available as of September 2025, the CES 2026 official announcement marks the first verification of technical feasibility.

However, questions remain about the escalating multi-color competition. Does increasing from 4 to 12 nozzles—and potentially beyond—truly address practical user needs? As systems grow more complex, calibration time, nozzle clogging risks, and component replacement frequency may all increase. While 50+ sensors and 4 AI cameras enhance self-diagnostic capabilities, they also add to overall system complexity. Where should manufacturers balance desktop convenience with industrial-grade sophistication? The evolution of multi-color functionality has reached a stage requiring not just technological competition among manufacturers, but realistic design considering actual operational burden on users.