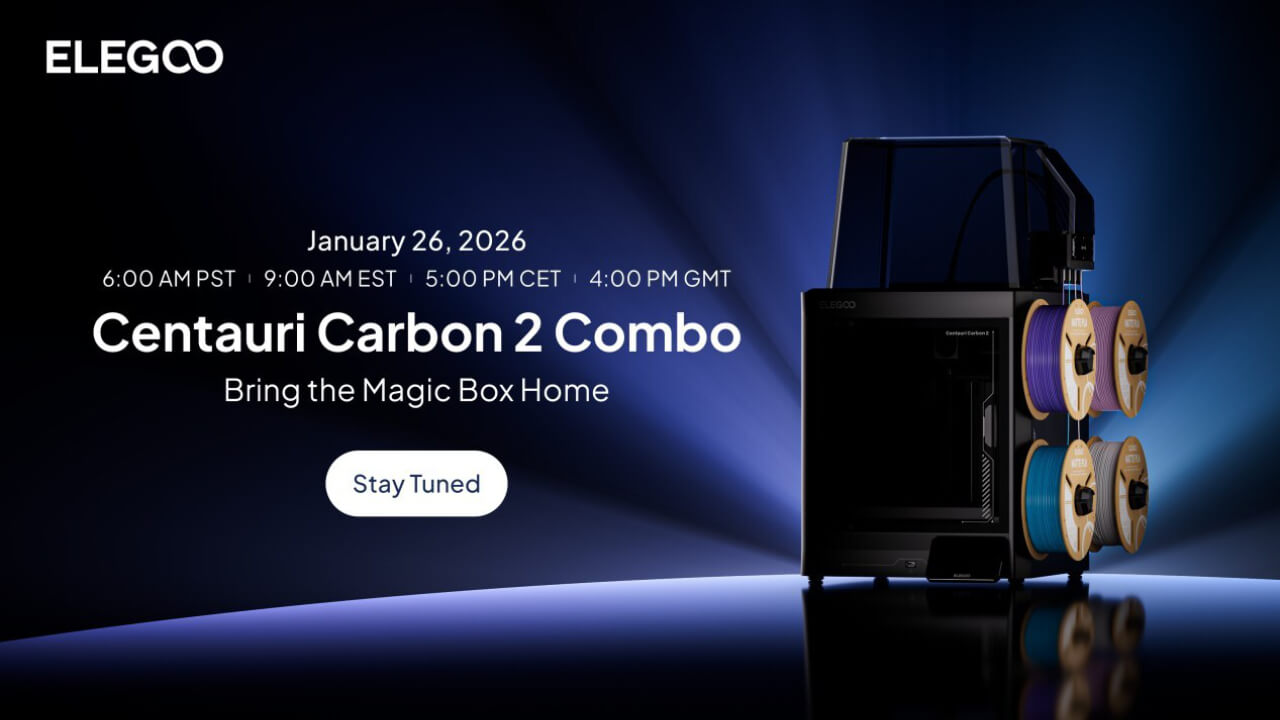

Shenzhen-based FDM 3D printer manufacturer ELEGOO has announced the launch of the ELEGOO Centauri Carbon 2, a multicolor desktop 3D printer, scheduled for release on January 26, 2026, at 5:00 PM CET / 9:00 AM EST. The ELEGOO Centauri Carbon 2 is positioned as a family-friendly desktop system designed for users ranging from beginners to professionals in home and office environments.

ELEGOO’s Market Position and Pricing Strategy

Since its founding in 2015, ELEGOO has experienced rapid growth through its strategy of “delivering high-quality hardware at competitive prices.” The company established its reputation with the Mars series of MSLA resin printers before entering the FDM market with the Neptune series. As of 2024, ELEGOO holds an 8.4% share of the consumer 3D printer market, positioning itself alongside major players like Creality and Anycubic.

The company’s distinctive characteristic lies in achieving specifications equal to or better than competing products while maintaining significantly lower price points. The Centauri Carbon, launched in 2025, delivered build size and performance comparable to the Bambu Lab X1 Carbon at a regular price of $413 (non-Carbon version at $199), shocking the industry. This pricing represented unprecedented value for a fully enclosed CoreXY printer and was evaluated as a product that challenged the market structure of traditional bed-slinger (moving bed) printers.

Key Features of the ELEGOO Centauri Carbon 2

The newly announced ELEGOO Centauri Carbon 2 inherits the strengths of its predecessor while integrating multicolor functionality. The standout feature is ELEGOO’s proprietary CANVAS system.

The CANVAS system provides the following capabilities:

- Smooth multicolor printing through automatic filament switching

- RFID-based automatic filament recognition

- Built-in filament backup to prevent print interruption

- Integration with Nexprint 3D model platform for automatic optimal setting recommendations

This configuration adopts an approach similar to competing systems such as Bambu Lab’s AMS (Automatic Material System), Creality’s CFS, and Anycubic’s ACE Pro.

In terms of technical specifications, enhancements include high-temperature nozzle support for expanded material compatibility, smart automatic bed leveling, and smart temperature control. Additionally, fundamental features have been strengthened, including quiet operation (45dB) and a 5-inch touchscreen supporting 11 languages.

Differentiation from Competing Products

The primary differentiation factors for the ELEGOO Centauri Carbon 2 include ELEGOO’s traditional strengths of “price competitiveness” and “ease of use.” While the official price will be announced on January 26, given the predecessor Centauri Carbon’s market-disrupting pricing strategy, the multicolor system-integrated model is likely to maintain significant price advantages over competitors.

ELEGOO’s strength lies in not compromising basic performance despite lower pricing. The Centauri Carbon series has captured market share by offering build volume, speed, and features comparable to competing products while maintaining substantially lower prices.

Another distinctive feature is the “ready to print out of box” design philosophy. Shipped partially assembled, users can begin printing without complex calibration procedures—a significant advantage for beginners.

Industry Trend Analysis

2025 has witnessed multiple major FDM printer manufacturers simultaneously launching multicolor/multi-material systems, indicating a clear trend shift in the desktop FDM market. Bambu Lab, Prusa, Creality, Snapmaker, Anycubic, and others—manufacturers occupying the majority of global market share—entering this domain simultaneously demonstrates both technological maturation and rising market demand.

Traditionally, multicolor FDM printing faced challenges including excessive purge waste, slow filament switching, and complex calibration requirements. However, 2025 models have significantly improved these issues through technological innovations such as induction heating toolheads, pre-heated modules, and purge tower reduction mechanisms.

ELEGOO’s ELEGOO Centauri Carbon 2 aligns with this market trend. The CANVAS system’s automatic filament management and Nexprint platform integration are particularly noteworthy for creating an environment where users with limited technical knowledge can access multicolor printing.

“Appropriate Machine” Over “Perfect Machine”

ELEGOO’s market strategy raises an important question in the 3D printing industry: namely, the recognition that users truly need not a “perfect machine” but rather “a product that balances price and functionality appropriate to their needs.”

This perspective incorporates lessons from industry history. Numerous companies that believed in the myth that “quality products sell regardless of price” and pursued technical perfection ultimately lost market position. Conversely, premium pricing has succeeded in certain market segments.

The smartphone market exemplifies this pattern. Apple’s iPhone and Samsung’s Galaxy series maintain market share while continuously raising prices because users demonstrate willingness to pay premium prices for added value such as “camera performance,” “processing speed,” and “ecosystem integration.”

Similar segmentation is occurring in the desktop FDM market. Bambu Lab has succeeded in the premium price range through added value including fully integrated ecosystems, AI-assisted failure detection, and cloud-based print management. Prusa gains support from educational institutions and SMEs through high quality standards and comprehensive support systems. Meanwhile, companies like ELEGOO and Creality achieve broader user accessibility by maintaining competitive pricing while ensuring basic performance.

What Functionality Do Users Actually Need?

The announcement of the ELEGOO Centauri Carbon 2 raises a more fundamental question: “Do users actually need multicolor functionality?”

In primary desktop FDM printer applications—rapid prototyping, jig fabrication, and hobby figure making—multicolor functionality is not an essential requirement. Indeed, many applications are adequately served by single-color printing. However, for product presentations, structural explanation models for education, and visualization of complex assemblies, multicolor functionality can deliver significant time savings and cost reductions.

The critical factor is not “having the functionality” but rather “whether that functionality justifies the price.” If adding a multicolor system doubles the price, purchasing two single-color printers might be more rational for many users. ELEGOO’s strategic advantage lies precisely in this price-performance balance.

Operational Differentiation Determines True Competitiveness

With technical implementation of multicolor functionality now standardized across manufacturers, the next differentiation factor is shifting toward “operational advantages.” Even with advanced features, products fail to gain user support if they present the following operational challenges:

- High print failure rates: Multicolor printing’s increased complexity makes troubleshooting more prone to issues such as filament jams, nozzle temperature instability, and inter-material adhesion failures

- Maintenance complexity: Systems with multiple filament paths require regular cleaning and calibration

- Consumable availability: Whether replacement parts such as nozzles, build plates, and filament tubes are readily accessible

- Support system absence: Whether appropriate technical support is available when problems occur

Furthermore, an often-overlooked challenge accompanying multicolor adoption is the complexity of filament management.

Filament Management Challenges Arising from Multicolor Adoption

Introducing a multicolor printer imposes new operational burdens on users. With single-color printers, maintaining inventory of 1-2 frequently used colors (typically black or white PLA) suffices. However, multicolor systems require simultaneous storage of multiple filament colors.

This situation closely resembles managing a paint set. When purchasing a 12-color paint set, only specific colors see frequent use, while rarely-used colors remain idle for extended periods, eventually hardening into unusability. For filament, the problem becomes more severe:

Moisture-induced degradation: Hygroscopic materials like PLA and nylon absorb atmospheric moisture, degrading print quality. Filament stored unused for several months can cause bubbling, stringing, and layer adhesion failures during printing. This issue becomes particularly pronounced in high-humidity Asian environments.

Color usage frequency imbalance: In practical multicolor printing, base colors (black, white, gray) see high consumption rates while accent colors (red, yellow, green) experience low usage frequency. Purchasing a 1kg spool of red filament for a 4-color system might result in actual usage of only several dozen grams. The remaining 900+ grams require proper storage to prevent degradation before next use.

Storage costs and equipment: Maintaining filament quality requires storage in sealed containers or dry cabinets. However, a 4-color system necessitates storing at minimum 4 spools, with consideration for future color changes potentially requiring 10+ spools. This involves not only physical space but also maintenance costs such as regular desiccant replacement.

Absence of small-volume packaging: Current markets primarily sell filament in 1kg spools. Small-capacity packages of 250g or 500g suitable for multicolor applications remain limited and tend toward premium pricing. Users face the dilemma of “being forced to purchase more than they can use.”

CANVAS System Functionality and Future Challenges

ELEGOO’s CANVAS system provides RFID-based automatic filament identification, instant filament loading, filament backup functionality, and automatic optimal setting recommendations through Nexprint platform integration. These features position the system as enabling beginners to easily initiate multicolor printing.

However, regarding responses to “filament storage degradation”—critical for long-term multicolor printer operation—information publicly available at present remains unclear. For example, functions such as recording filament usage start dates and notifying recommended expiration periods, monitoring storage environment (temperature/humidity), predicting material consumption, and recommending re-drying timing for unused filament could substantially reduce user operational burden if available.

The presence or absence of such operational support features will become clear with the official announcement on January 26.

Market Response to These Challenges

With multicolor market expansion, the following changes are anticipated:

- Small-volume filament package proliferation: Manufacturers may add 250g-500g small-capacity packs to standard lineups

- Subscription model emergence: Services delivering needed colors in needed quantities on regular schedules

- Refill system development: Mechanisms for reusing spools while replenishing only filament

- Desiccant-integrated spool holders: Designs integrating moisture-proof functionality into printer bodies

Whether ELEGOO will provide such filament management solutions alongside the ELEGOO Centauri Carbon 2remains unclear, but this represents an equally important element as technical specifications for multicolor printer adoption.

Comprehensive Operational Design Determining Practical Utility

ELEGOO’s existing products, particularly the Centauri Carbon, have earned evaluation for “ready to print out of box” design and relatively stable print quality. Tom’s Hardware’s review noted “This entry-level 3D printer delivered performance nearly matching $1000-class machines in testing,” establishing fundamental performance reliability.

Whether the ELEGOO Centauri Carbon 2 maintains this operational reliability will become a critical factor determining market success. The CANVAS system’s automatic filament management, RFID material recognition, and filament backup functionality represent manifestations of design philosophy aimed at “reducing failures.”

However, true operational capability is determined not solely by printer body functionality but by the “entire ecosystem” including filament storage, consumable supply, and troubleshooting support response.

Furthermore, ELEGOO’s track record of selling products in over 100 countries globally suggests certain advantages in parts supply network construction. Consumable accessibility directly impacts long-term operational costs, making it an equally important selection criterion as price competitiveness.

Manufacturer “Vision” and User “Necessity”

Ultimately, whether the ELEGOO Centauri Carbon 2 gains market acceptance depends on three factors:

- Pricing: How much users are willing to pay for multicolor functionality

- Operational reliability: The degree of trouble-free experience deliverable in actual use

- Total operational cost: Actual running costs including filament management, consumable replacement, and storage equipment

The official price will be announced on January 26, and how ELEGOO balances these factors will serve as an important indicator of future desktop FDM market direction.

The desktop FDM market follows an evolutionary path distinct from industrial AM equipment markets. Consumer markets prioritize price competitiveness and usability, while industrial applications prioritize precision, reproducibility, and material properties. Companies like ELEGOO targeting the intermediate domain—products maintaining professional functionality while preserving price and accessibility—indicates desktop FDM market maturation.

In Asian markets, particularly Chinese manufacturing, desktop FDM equipment usage in product development rapid prototyping stages is increasing. For these applications, “rapid iteration” and “cost efficiency,” along with “stable operation,” take priority over “perfect surface finish.” How well products like the ELEGOO Centauri Carbon 2 can address these practical requirements, including filament management, will determine true market value.

As an implication for the entire industry, the focus should shift from multicolor functionality being evaluated for what it “can do” to how it “can be operationally managed” on a daily basis. From competition on technical specifications to ease of actual use, long-term cost efficiency, and overall ecosystem completeness—this transition should define the next maturation stage of the desktop FDM market.

Sources: