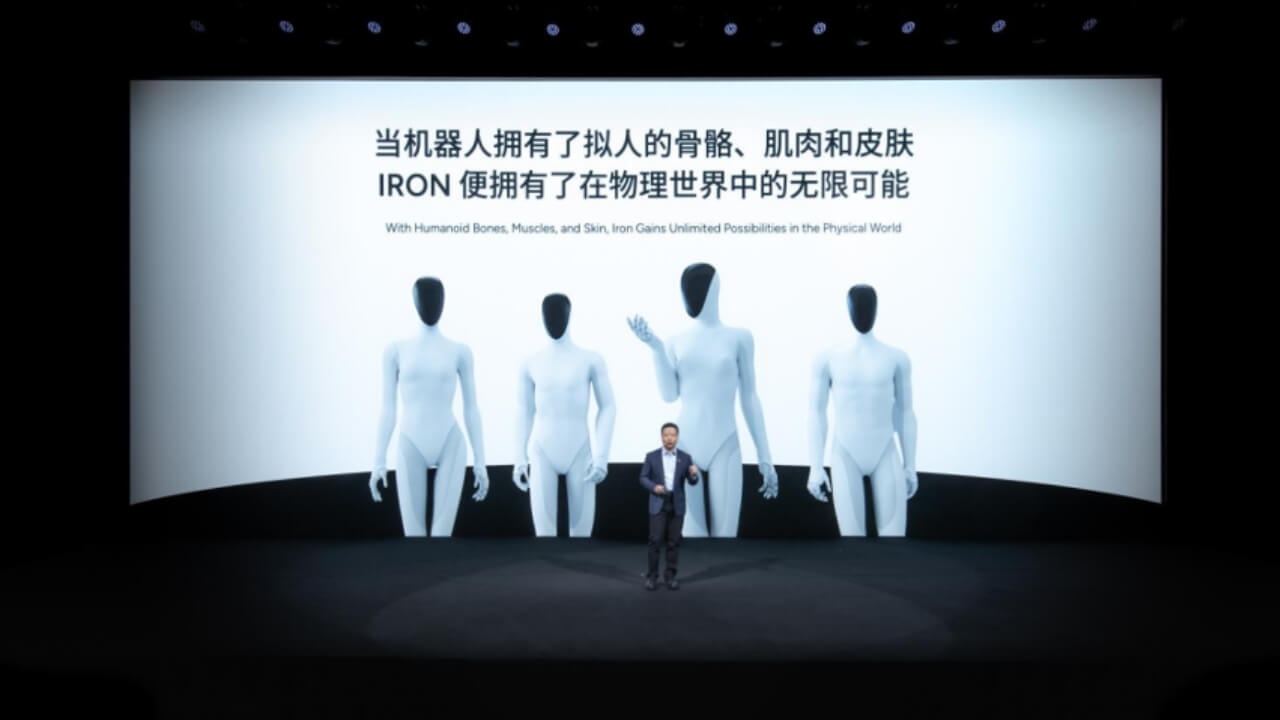

Behind Xpeng’s viral robot IRON lies PollyPolymer’s ambitious market expansion strategy. In 2025, Chinese automaker Xpeng unveiled its humanoid robot “IRON,” which captivated social media with its remarkably human-like movements. According to the South China Morning Post, the technology behind this lifelike motion—bionic “muscles”—comes from PollyPolymer, a company based in Suzhou, Jiangsu Province, China. The gait was so natural that suspicions arose about a person being inside, prompting founder He Xiaopeng to unzip the robot’s back on stage to reveal its internal structure.

Video: Cutting Open IRON — The Truth Behind this Robot. Source: Xpeng

https://www.youtube.com/watch?v=m_Ag_SgsHVg

What emerged was not conventional motors or linkages, but a cream-colored mesh structure. This “bionic muscle” enables the robot’s fluid, human-like motion.

Ultra-Fast 3D Printing Born from Footwear

PollyPolymer was founded in 2017 by materials expert Wang Wenbin. The company developed mature 3D printing technology for footwear in 2019, and shoes remain its core business, accounting for 60% of total revenue.

The company’s competitive advantage lies in its proprietary “HALS (Hindered Asynchronous Light Synthesis)” 3D printing technology. According to Wang, this technology achieves printing speeds up to 100 times faster than conventional 3D printing. Additionally, the company possesses approximately 10,000 material formulations, enabling diverse applications.

As of 2025, PollyPolymer’s annual shoe manufacturing capacity has reached 2 million pairs. Wang revealed plans to double this capacity to 4 million pairs in 2026. The company collaborates with brands including Cole Haan, Skechers, and Peak Sport Products, supplying components such as highly elastic soles and lightweight uppers, as well as manufacturing entire shoes as monolithic pieces.

A notable case study involves The Walt Disney Company’s presentation at Shanghai Fashion Week in 2024, featuring 3D-printed accessories and footwear. PollyPolymer was “responsible for material research and development for footwear, bags and accessories, alongside 3D printing technical support” for this project. According to Wang, this approach, which eliminates the need for traditional molding, reduced development time by 70%.

Entry into Humanoid Robotics

However, PollyPolymer’s ambitions extend beyond footwear. Wang states that the company has “established joint research and development partnerships with several leading robotics companies, including more than 20 from China.”

In addition to Xpeng’s bionic muscles, PollyPolymer has developed joint cushioning kits for UBTech Robotics and integrated foot kits for EngineAI.

Bionic muscles for humanoid robots require specialized materials. According to Wang, these materials “must simultaneously meet four core requirements: high elasticity, excellent heat dissipation, superior wear resistance and anti-ageing properties.” PollyPolymer achieved an elongation rate of 300% while maintaining a skin-like texture through molecular structure modification.

Global Expansion and Cross-Industry Strategy

PollyPolymer positions itself not only as a consumer goods manufacturer but also as an industrial R&D partner. According to Wang, the company supplies 3D-printed prototypes to Samsung Electronics and Bosch, “helping improve their R&D efficiency” rather than manufacturing final products.

Currently, 25% of the company’s revenue comes from customers outside China, with annual growth exceeding 40%. Wang aims for overseas markets to contribute more than 50% of total revenue within three years.

As part of this strategy, PollyPolymer launched its own consumer brand, “PollyFab.” According to Wang, this brand targets “the youth market overseas and tech enthusiasts in China,” initially covering three product categories: customized sneakers, accessories such as keychains, and home decor with cultural and creative elements. In 2026, PollyFab plans to establish brick-and-mortar stores in major markets including the United States, France, and Japan.

China’s Robotics Race and AM’s Role

PollyPolymer’s case demonstrates the critical role of 3D printing in China’s humanoid robot development.

Xpeng founder He Xiaopeng stated in a recent interview that once the robotics industry crosses its technological and product inflection point, the global robotics market could reach $20 trillion over the next 10-20 years—roughly twice the size of the automotive sector.

3D printing plays a significant role in humanoid robot development. While traditional robots rely on rigid metal frames, 3D printing enables the manufacture of flexible, lightweight elastomers. Vitalbridge Capital, an early investor in PollyPolymer, notes that “materials innovation has become a key factor in the evolution of embodied intelligence.”

Beyond weight reduction, 3D printing contributes to shortened development cycles. While traditional mold-making requires months, projection-based curing technologies such as DLP (Digital Light Processing) enable designing, printing, and testing new actuator geometries within days. Monolithic manufacturing reduces part count and eliminates adhesive or fastener interfaces, simplifying assembly and maintenance.

The Significance of Cross-Industry Business Models

PollyPolymer’s trajectory from footwear to robotics demonstrates a business model characteristic of Chinese AM companies. By horizontally deploying the same foundational technologies (ultra-fast DLP, elastomer materials) across multiple industries, the company simultaneously achieves scale advantages and technological maturity.

Globally, companies like Carbon (USA) and Stratasys (USA/Israel) also apply high-speed photopolymerization to footwear and healthcare devices, while chemical manufacturers such as BASF (Germany) and Wacker Chemie (Germany) are developing elastomers for robotics and wearable systems. However, the rapid vertical integration from consumer goods to robotics seen in PollyPolymer’s case is a distinctive characteristic not observed in these companies.

PollyPolymer’s case indicates that Chinese AM companies are maturing from the R&D phase to the mass production phase. The fact that a company manufacturing 2 million shoes annually can leverage its technological foundation to enter the robotics industry suggests that Asia’s AM sector is entering a new phase.