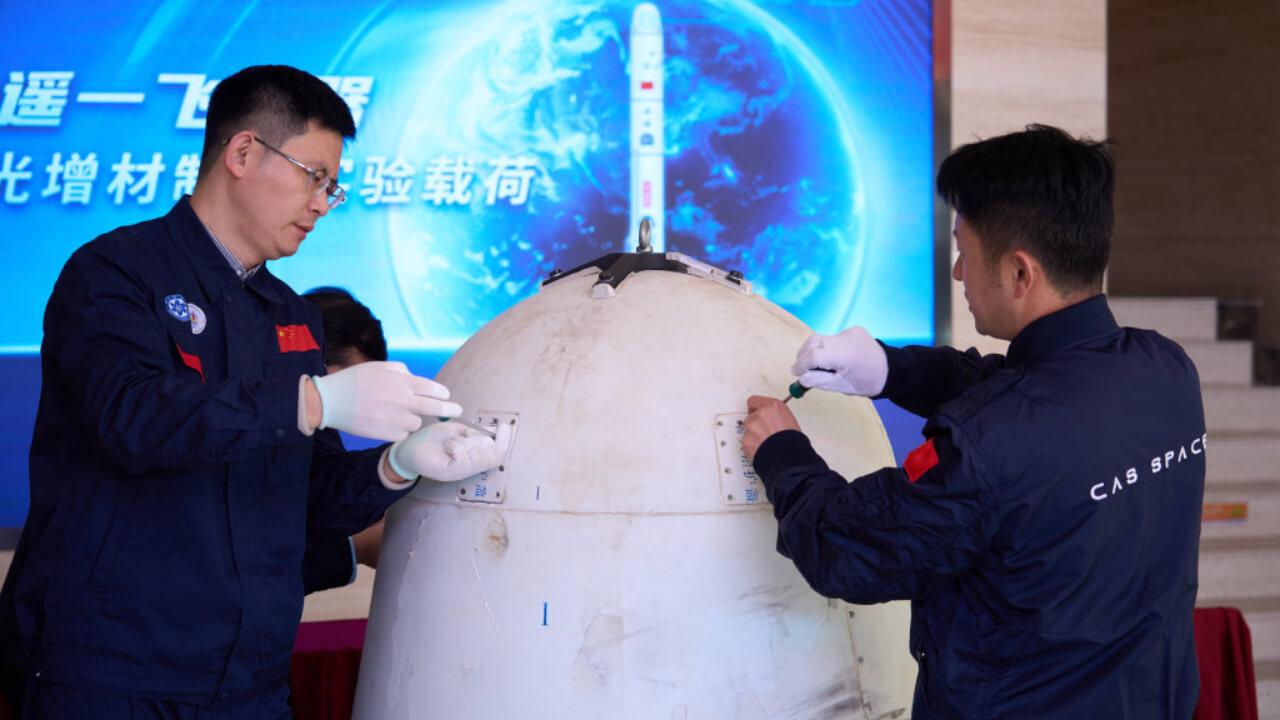

The Chinese Academy of Sciences (CAS) Institute of Mechanics has successfully completed China’s first space metal 3D printing experiment, marking a significant advancement in orbital manufacturing capabilities. According to Xinhua, the experiment was conducted aboard the Lihong-1 Y1 suborbital spacecraft launched from the Jiuquan Satellite Launch Center on January 12, 2026.

Why Space Manufacturing Presents Unique Challenges

Space-based metal 3D printing faces fundamentally different conditions than terrestrial manufacturing. In microgravity environments, melt pool behavior, material flow dynamics, and heat dissipation operate under entirely different physical principles. Traditional powder bed fusion methods cannot function without gravity to hold powder layers in place, making wire-fed approaches the only viable option for orbital manufacturing.The CAS research team overcame a series of critical technical challenges, including stable material transport under microgravity conditions, full-process closed-loop control systems, and high-reliability coordination between the payload and launch vehicle.

Wire-Fed DED Technology Enables Microgravity Manufacturing

The experiment reached an altitude of approximately 120 kilometers and autonomously fabricated metal components during a microgravity environment lasting over 300 seconds. According to Global Times, the system utilized laser wire-fed directed energy deposition (DED) technology, specifically chosen for its compatibility with space conditions.

Unlike powder bed fusion methods that rely on gravity, wire-fed DED controls material delivery mechanically, making it practical for microgravity additive manufacturing. The technology also builds on decades of proven welding and laser cladding expertise, offering reliability crucial for mission-critical space applications.

Technical Breakthrough and Data Collection

The CAS research team successfully obtained first-hand data on melt pool dynamics, material transport, solidification behavior, and structural precision. Following the experiment, the payload capsule safely landed via parachute and was recovered for detailed analysis.

This marks China’s transition from ground-based research to in-space engineering verification in space-based metal manufacturing. The successful experiment places China in a select group of nations developing orbital manufacturing capabilities. The European Space Agency previously demonstrated metal 3D printing aboard the International Space Station, while NASA continues advancing lunar surface manufacturing technologies for future missions.

Future Applications in Space Infrastructure

The technology is expected to enable on-orbit component manufacturing and autonomous repair, significantly reducing dependence on ground resupply for deep space exploration and long-term space station operations. Wire-fed DED is also gaining traction in tooling repair and industrial equipment maintenance sectors, indicating growth potential in both space and terrestrial applications.

Specific applications include on-demand manufacturing of satellite spare parts, production of structural components for space stations, and fabrication of tools for lunar or Martian habitats. By eliminating the need to launch every component from Earth, this technology could dramatically reduce mission costs while enabling unprecedented mission autonomy for deep space exploration.