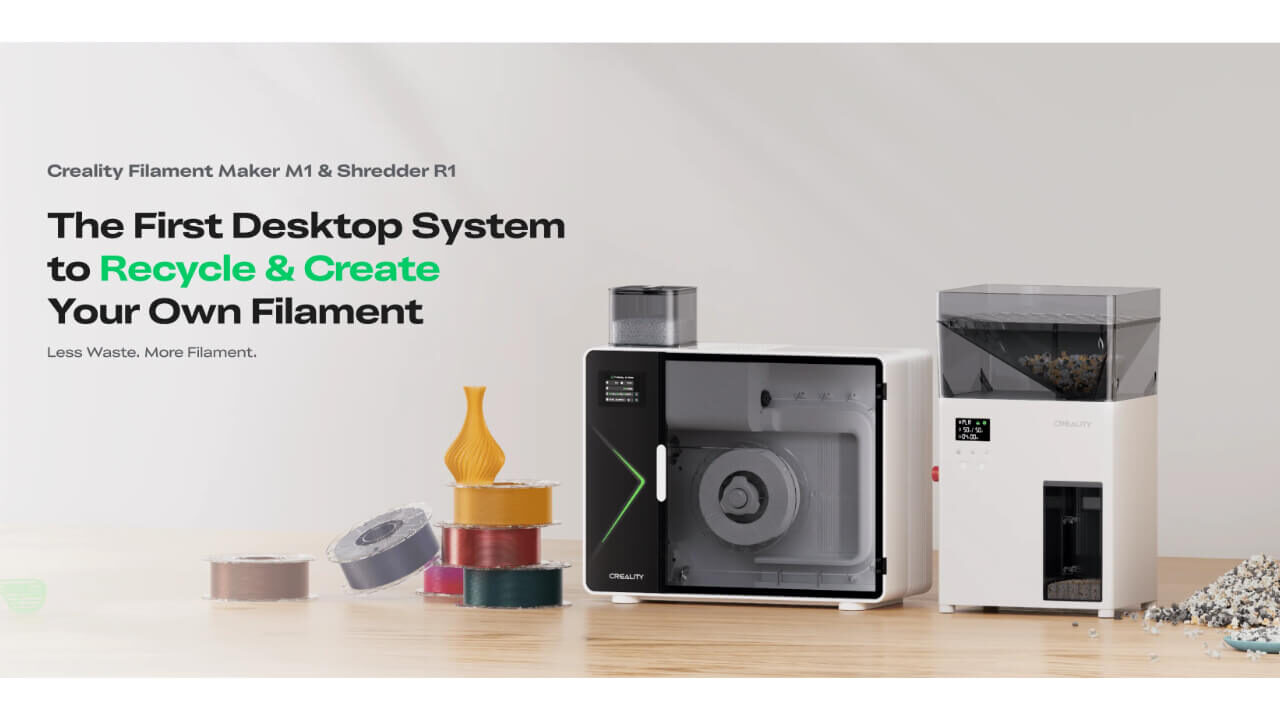

Leading Chinese 3D printer manufacturer Creality has unveiled a desktop filament recycling system that enables users to transform printing waste into new filament. The Filament Maker M1 and Shredder R1 combination creates a closed-loop workflow for sustainable 3D printing.

As multicolor 3D printing gains popularity, the disposal of waste material from filament changes and failed prints has become a significant challenge for creators worldwide. Creality’s new recycling system offers an innovative solution to this growing environmental concern.

Industry-Leading Production Capacity

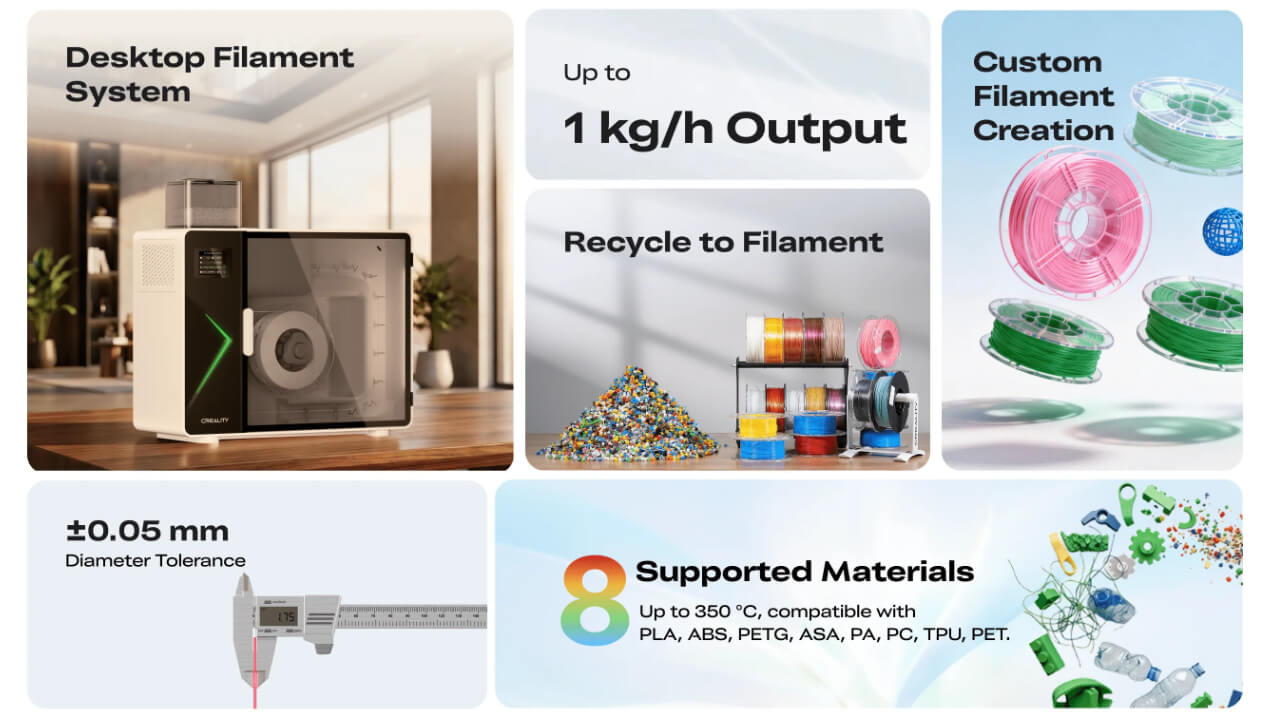

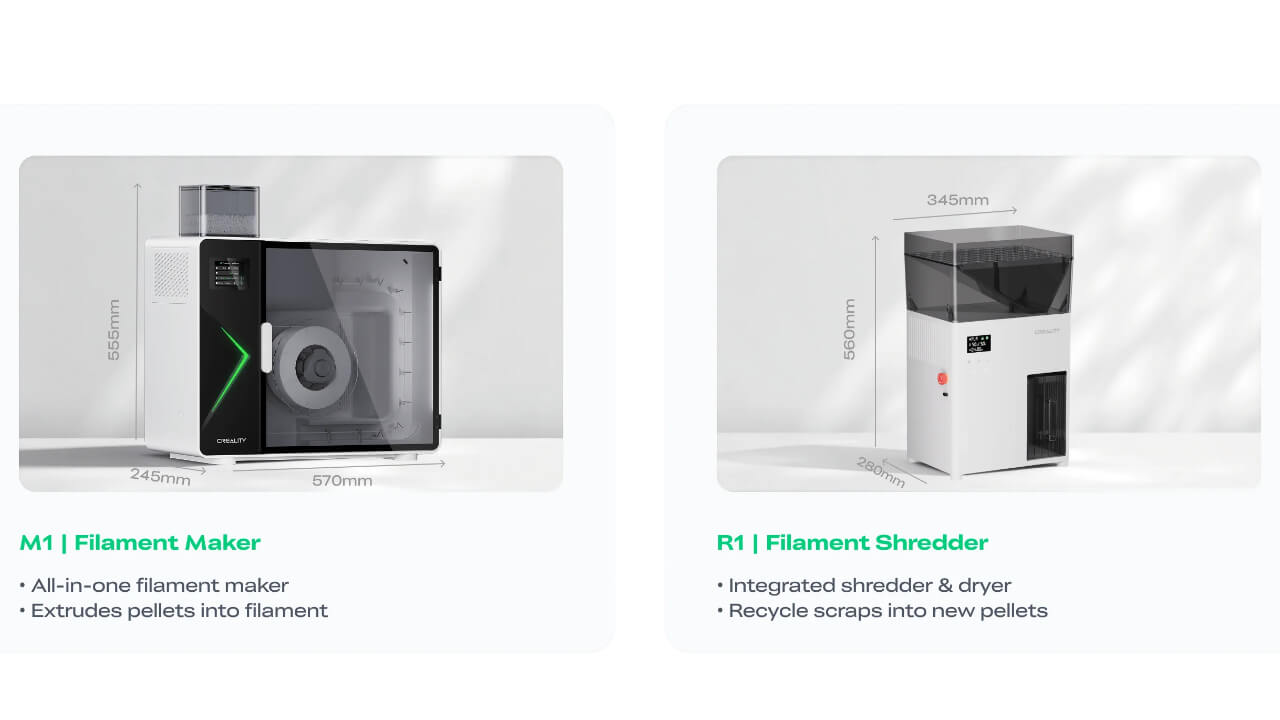

The Filament Maker M1 converts plastic pellets—whether virgin or recycled material—into standard 1.75mm filament. With a production capacity of 1 kilogram per hour, the system delivers superior efficiency compared to competing desktop solutions in the market.

The device maintains diameter tolerance within ±0.05mm, ensuring compatibility with most consumer-grade 3D printers and reliable print quality. Operating at temperatures up to 350°C, the M1 supports at least eight common printing materials, including PLA, ABS, and TPU.

Complete Closed-Loop Workflow from Waste to Filament

The core innovation of this filament recycling system lies in the integrated workflow between the M1 and R1 units:

Shredder R1 (Shredding & Drying Unit)

The R1 processes failed prints, support structures, test pieces, and multicolor printing waste into uniform particles while simultaneously drying the material. This moisture removal ensures optimal raw material preparation for high-quality filament production.

Filament Maker M1 (Filament Manufacturing Unit)

Processed recycled pellets or new commercial pellets are fed into the M1. Through a precision temperature-controlled heating extrusion system, the pellets are melted and extruded through a patented nozzle design. After cooling and intelligent winding, the result is a spool of high-quality, ready-to-use filament.

This entire process can be completed on a desktop, truly realizing the vision of “waste stays in, new filament comes out.”

Material Sovereignty in Users’ Hands

Beyond environmental benefits and cost reduction, the desktop filament recycling system grants users unprecedented “material sovereignty”:

Color Customization: Freely mix PLA waste of different colors to create unique color blends, marble patterns, or gradient effects.

Performance Experimentation: Mix pellets with different properties (such as adding TPU to PLA for increased toughness) or adjust manufacturing parameters to fine-tune filament performance.

Personalized Additions: Theoretically, users can experiment with adding safe fragrances or glitter particles to create custom filaments with unique scents or special visual effects.

Crowdfunding Campaign Now Open

The system features a smart-guided operation interface, patented pellet feeding mechanism, and an activated carbon filtration system that absorbs odors and fine particles during operation.

Currently, pre-orders are available through Creality’s official crowdfunding platform (https://crowdfunding.creality.com/). While specific pricing has not been announced, the system is expected to be positioned in the “advanced” desktop equipment price range due to its integrated functionality.

Analysis: Circular Economy Comes to Desktop Additive Manufacturing

Creality’s move signifies more than a simple product launch.

First: Strategic Shift from Hardware to Ecosystem

This represents a strategic transition by a 3D printer manufacturer toward “ecosystem” solutions. Of course, filament shredders and extruders have existed previously, with startups like Filastruder, Felfil, and 3Devolution offering similar products. However, these were standalone products requiring users to research, source equipment from multiple vendors, and verify compatibility themselves.

Creality’s innovation lies in the 3D printer manufacturer itself providing integrated solutions encompassing not just the printer but the entire surrounding environment. By creating the waste problem with multicolor printers like the SPARKX i7, while simultaneously offering the M1/R1 solution, Creality demonstrates a shift from selling individual products to “ecosystem sales”—an Apple-like vertical integration strategy. This approach ensures user experience consistency, interoperability guarantees, and brand loyalty building, positioning the company one step ahead.

Second: Potential Business Model Transformation

This filament recycling system could fundamentally reshape the desktop 3D printing business model. Traditionally, filament manufacturers have sold materials as “consumables” to users continuously. However, if the M1/R1 system becomes widespread, users may purchase inexpensive pellets or self-recycle, potentially eroding portions of the existing filament market.

Third: Strategic Advantages of Chinese Manufacturers

As one of the world’s largest desktop 3D printer manufacturers, Creality has been promoting multicolor printing with latest models like the SPARKX i7. The M1/R1 serves as a “complementary product,” strategically locking in users across the entire ecosystem. The timing of this release, immediately following the SPARKX i7 announcement at CES 2026, appears calculated.

Fourth: Western Market Reception as Litmus Test

Environmentally conscious maker communities in Western markets will likely welcome this sustainability-focused concept. However, market penetration will depend on factors including the payback period for initial investment (combined M1+R1 cost) versus material savings, quality consistency, and safety (filter effectiveness).

Fifth: Innovation Direction in Asian AM Industry

This symbolizes the innovation direction of Asia’s AM industry. While Western companies focus on technological innovation in industrial large-format equipment, Chinese companies differentiate through ecosystem building, convenience, and cost-performance in the consumer market. This competition between “top-down innovation” versus “bottom-up innovation” will intensify.

The results of Creality’s crowdfunding campaign and responses from competitors (Bambu Lab, Prusa, etc.) will be noteworthy. Particularly, Bambu Lab, having taken the lead with its AMS (Automatic Multi-Material System), may introduce a similar recycling solution.